200-300kgh mobile pellet line

200-300kg/h Mobile Pellet Line consists of main machines: screw conveyor, Crushing machine, ring die pellet mill, Cooler, Grading sieve machine, dryer, packing machine, etc. It can be removed near to raw material and reduce transportation cost of raw material. It is excellent to be owned by a farm.

Host machine adopts gear drive system, so that it has perfect transmission ratio. It is optimized with big driving torque, smooth transmission, easy operation and low maintenance costs.

Users can choose different aperture and the compression ratio according to different needs for the best technical and economic benefits.

Photos of Mobile Pellet Line:

Key Parameter:

Capacity: 200-300kg/h. Dia. 6mm pellet

Pellet Density: 1.1-1.3g/cm3

Raw Material Moisture: 12-15%

Pellet Rate: ≥95%

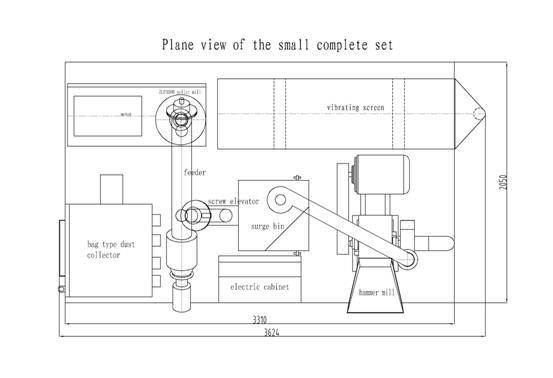

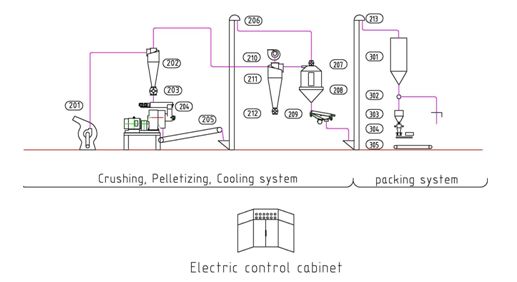

Flow Chart of C22 Mobile Pellet Line:

|

No. |

Description of Crushing, Pelletizing, Cooling machine |

|

1 |

Hammer mill |

|

2 |

Cyclone |

|

3 |

Air lock |

|

4 |

Wood pellet mill |

|

5 |

Screw conveyor |

|

6 |

Bucket elevator |

|

7 |

Air lock |

|

8 |

|

|

9 |

Sieve machine |

|

10 |

Fan |

|

11 |

Cyclone |

|

12 |

Air lock |

|

13 |

Bucket elevator |

|

No. |

Description of Packing machine |

|

1 |

Pellet storage bin |

|

2 |

Three-way |

|

3 |

Waiting hopper |

|

4 |

|

|

5 |

Sealing machine |

Note:

This plant is used to process straw, sawdust and other biomass materials without drying. So the moisture of your raw material need be about 15%, and the size be less than 50mm.

Of course this Bioy-C22 mobile pellet plant can also go with dryer if the moisture of your raw material is higher than 15%, or match packing machine according to the request of customers.

The power of this complete wood pellet plant is 37kw, and size of required workshop is 4200*2000*4000mm.