Electric Pellet Mill

There are two kind of electric pellet mills, they all are suitable to produce wood pellet. We got some feedback from our customers after

they used our flat die pellet press. They gave us some suggestions about operating this machine to produce wood pellet. Hope it is helpful for you:

1) Best moisture is 15% for all materials

2) The temperature is constant bewteen 90-95'C, you have to take over the pellet just coming out from this pellet press and cooling it before touching it by hand.

Furthermore, we improved our machine to be more suitable to produce wood pellet after absorbing & digesting the feedback from our customers.

3)Special raw material on the main parts such as roller, template, matrix, prolonging the life than other similar products in China when process wood pellet

after this modification.

4)Modify the whole in the matrix to improve performance of the machines. It's easier to make pellet.

5) We have got the CE Certificate from SGS to meet EU client's requirement.

1.2. Overview

| Type | Capacity | Power (kw) | Dimension (mm) | NG/GW (kg) |

| ZLSP-200 R-Type | 100-200KG/h | 7.5kw,3phase | 1150*560*750mm | 300kg |

| ZLSP-300 R-Type | 250-350kg/h | 22kw,3phase | 1350*650*800mm | 420kg |

| ZLSP-350 R-Type | 450-500kg/h | 30kw, 3phase | 1650*1000*1200mm | 800kg |

| ZLSP-450 R-Type | 600-700kg/h | 37kw, 3phase | 1800*1100*1350mm | 1100kg |

| ZLSP-550 R-Type | 850-1000kg/h | 45kw, 3phase | 2000*1000*1500mm | 1500kg |

|

|

| Rotating Roller Pellet Mill | Spare Parts of Pellet Mill |

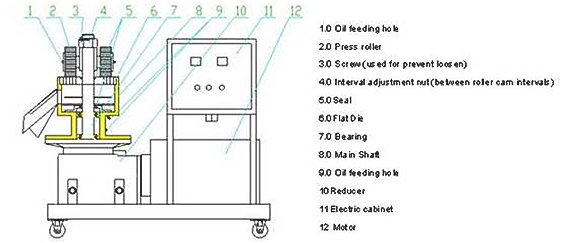

Pellet Mill Structure

Lubrication:

1. Lubricating the bearing.

2. Lubricating the gears in gear box.

1. The gear of gear box uses high quality alloy steel with nitrogencase hardening dispose and grinded accurately and particularly;

2.The main shaft is allocated with heavy load Thrust Bearing which can bear strong axial force, and has long user life.

Noted: the capacity above is used to process sawdust, straw, stalk, wood chips, and other biomass materials.

|

|

|

|

|

Type

|

Capacity

|

Power (kw)

|

Dimension (mm)

|

Weight (kg)

|

| ZLSP200B D-Type | 100-150kg/h | 7.5kw, 3phase | 1000*430*950mm | 230kg |

| ZLSP230B D-Type | 150-200kg/h | 11kw, 3phase | 1140*470*970mm | 320kg |

| ZLSP260B D-Type | 200-300kg/h | 15kw, 3phase | 1200*500*1070mm | 360kg |

| ZLSP300B D-Type | 350-400kg/h | 22kw, 3phase | 1270*520*1070mm | 450kg |

| ZLSP360 D-Type | 400-450kg/h | 22kw, 3phase | 1270*520*1070mm | 500kg |

| ZLSP400 D-Type | 450-500kg/h | 30kw, 3phase | 1470*600*1150mm | 585kg |

Noted: the capacity above is used to process sawdust, straw, stalk, wood chips, and other biomass materials.

|

No.

|

Name

|

Qty

|

No.

|

Name

|

Qty

|

| 1 | Upper hopper | 1 | 20 | Big bearing cap | 1 |

| 2 | Adjusting screw | 2 | 21 | Discharge plate | 1 |

| 3 | Upper shell | 1 | 22 | Main shaft big bearing | 1 |

| 4 | Lower shell | 1 | 23 | Main shaft small bearing | 1 |

| 5 | Dipstick | 1 | 24 | Connect gear plate | 1 |

| 6 | Checking window | 1 | 25 | Bevel gear | 1 |

| 7 | Output gate | 1 | 26 | Pressuring roller bearing | 4 |

| 8 | Gear-box | 4 | 27 | Pressuring roller | 2 |

| 9 | Base wheel | 1 | 28 | Template/die | 1 |

| 10 | Current meter | 1 | 29 | Horizontal shaft big bearing | 1 |

| 11 | Voltmeter | 1 | 30 | Horizontal shaft cover | 1 |

| 12 | Electricity box | 1 | 31 | Angle gear | 1 |

| 13 | Electricity box support | 1 | 32 | Horizontal shaft small bearing | 1 |

| 14 | Basis | 1 | 33 | Framework oil seal | 1 |

| 15 | Generator | 1 | 34 | Cushion | 1 |

| 16 | Pressuring roller bearing cover | 1 | 35 | Gibbosity | 1 |

| 17 | Main shaft cap.lock . flat ring | 1 | 36 | Initiative shaft coupling | 1 |

| 18 | Main shaft | 1 | 37 | Passivity shaft coupling | 1 |

| 19 | Knife | 1 |

Small Pellet Mill

- For Different Models

- For Different Materials

Large Pellet Mill

Biomass Pellet Plant

Auxiliary Machinery