Flushing a New Die

Home > Instruction Book >

Before using

pellet mill, the die should be flushed. This process removes any burrs that may remain after the manufacturing process. To do so, mix raw materials with fine sand at a ratio of 5:1. One part of oil should also be added to the mixture. Adjust the bolt that controls the distance between the die and the roller until pelleted output results. Recycle the discharged material through the machine. The process should be repeated for between ten minutes to one hour as needed, and is especially important for dies with small-diameter openings. The result will be more stable production and increased pellet quality.

Product List

COMMENTS

Charles Avery

AUS

Kelly Kulp

USA

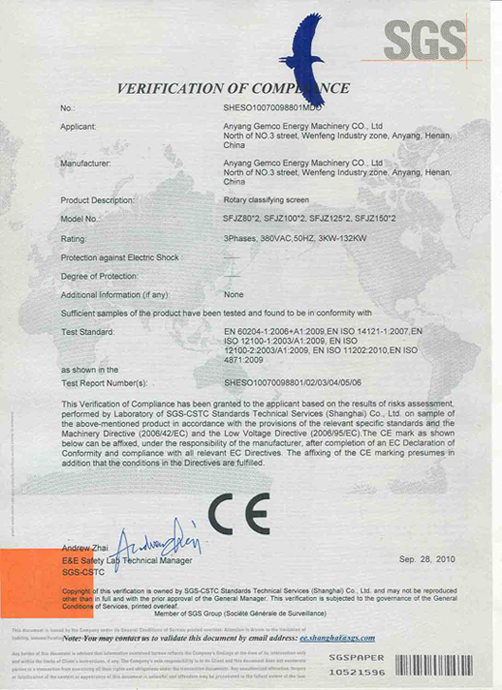

AGICO GROUP © Copyright 2012 | Privacy policy Anyang Gemco Energy Machinery Co.,Ltd E-mail: sales@chinapelletmill.com