FAQs About Biomass Pellet Plants

1. What are the main processes of a biomass pellet plant?

Crushing, drying, pelleting, cooling and packing.

2. What is the biomass pellets' moisture content after cooling?

7%-8%

3. What's the optimal moisture content of the feed prior to entering the pellet mill?

14%-16%

4. What kinds of materials can be used to make biomass pellets?

Numerous materials can be used. This includes, but is not limited to: sawdust, coffee husks, paddy straw, sunflower stalks, cotton stalks, tobacco waste, mustard stalks, jute waste, bamboo, tea waste, wheat straw, palm husks, soybean husks, rice husks, forestry waste and wood chips.

Product List

COMMENTS

Charles Avery

AUS

Kelly Kulp

USA

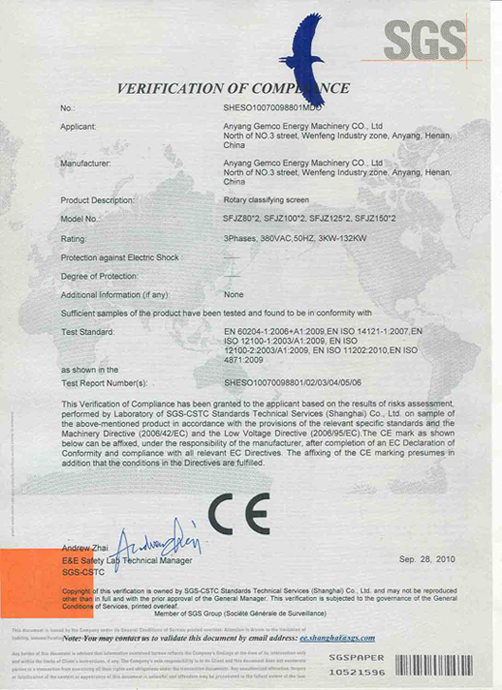

AGICO GROUP © Copyright 2012 | Privacy policy Anyang Gemco Energy Machinery Co.,Ltd E-mail: sales@chinapelletmill.com